Since the 1990s, the "circular economy" has become one of the most used terms in business, centered on recycling, reducing waste and creating sustainability. The automotive industry, known for its high costs, is in fact one of the most profitable sectors in this new environmental revolution, with everything from tires to body shells being perfect for recycling, remanufacturing and reuse.

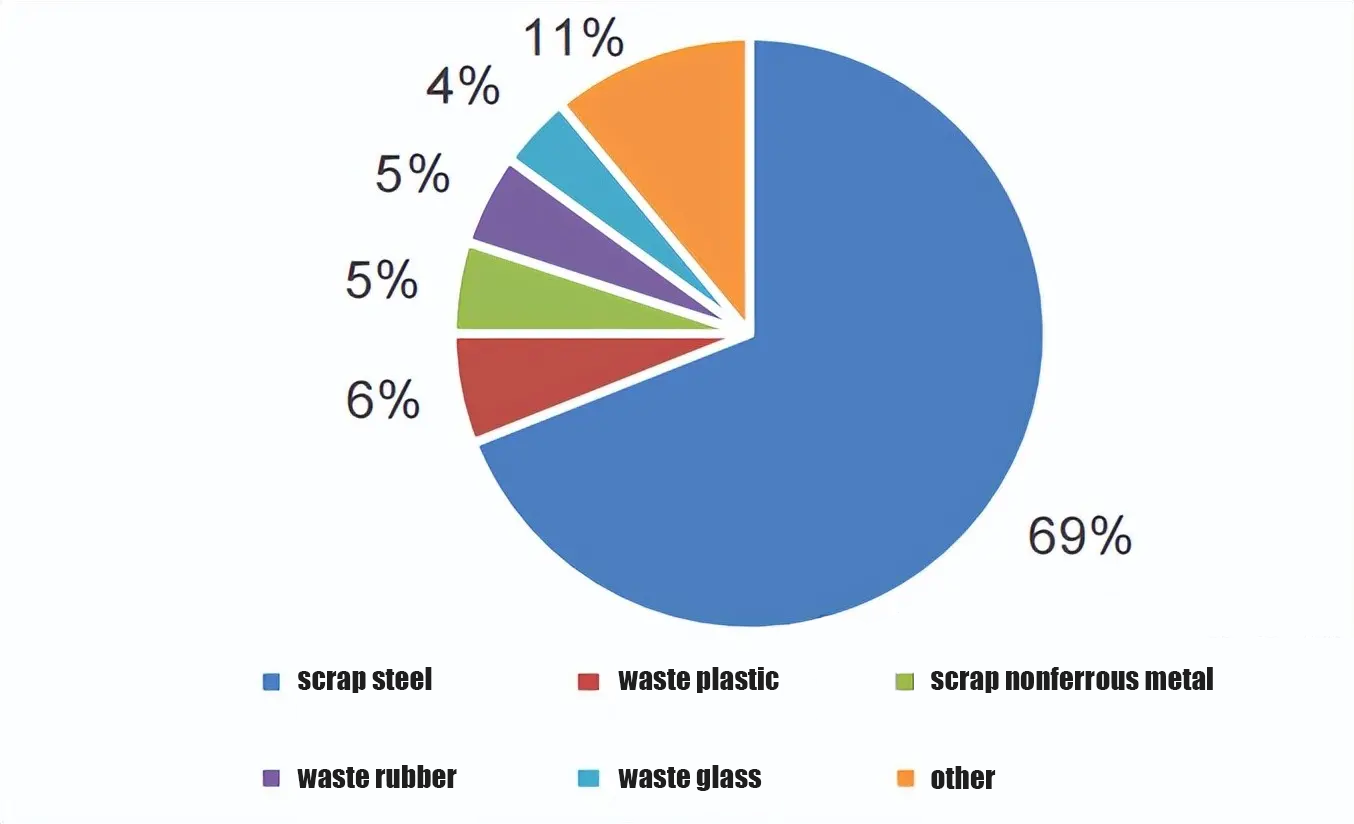

Composition of recycled and dismantled materials per end-of-life vehicle

The global automotive parts market is expected to reach $350 billion by 2025, growing at a compound annual growth rate (CAGR) of 7%. This market growth will be driven primarily by digitalization and electrification trends. And between now and 2030, the development of a circular economy in the automotive industry represents a huge market potentially worth 4.1 trillion euros, according to consulting firm Accenture.

The International Labor Office estimates that such a transformation could create 6 million jobs worldwide and that companies could replace the traditional "make, use, throw away" linear economy with a "extract, make, use and recycle" circular model. The model is a "make, use and throw away" linear economy. Each vehicle can generate 15-20 times its sales price over its entire life cycle. In a modular vehicle design, production is the largest cost, but 1.5-4 times more profitable in the maintenance phase, and another 2-5 times more profitable in end-of-life recycling.

Currently, in most countries and regions, recycling is driven by regulations.

In China, the Ministry of Industry and Information Technology, the Ministry of Science and Technology, the Ministry of Finance and the Ministry of Commerce issued the Notice on the Issuance of the Pilot Implementation Plan for the Extension of Producer Responsibility for Automotive Products in 2021, through which the pilot program will achieve a 75% utilization rate of recycled resources for end-of-life vehicles, a 95% utilization rate for recyclable vehicles, and a minimum of 5% utilization of recycled raw materials for key components by 2023.

Japan and South Korea have had vehicle recycling laws for more than 15 years. In Japan, the recycling ratio of end-of-life vehicles is 75%-80% by weight, and South Korea is nearly 90%. Meanwhile, India also introduced an end-of-life framework similar to the EU ELV in August 2021. In the U.S., there is no federal law on the subject, and legislation and requirements for vehicle recycling exist in only a few states.

Some interest groups are even hoping that the legislation will go further, pushing the industry to move from an "open-loop" recycling policy (allowing materials to be converted into other products) to a "closed-loop" policy (converting materials into new versions of the original product).

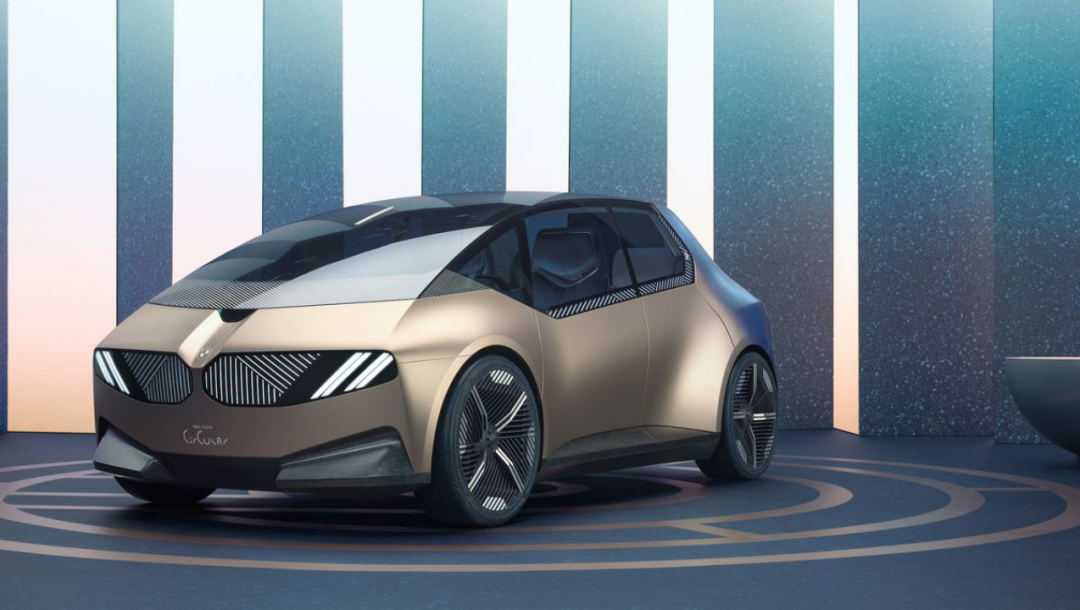

BMW i Vision Circular (100% recyclable materials)

Advances in technology and innovation are playing a key role in driving the circular economy in the automotive industry, from the use of efficient and sustainable materials, to advanced sorting and disassembly techniques, to improved remanufacturing processes.

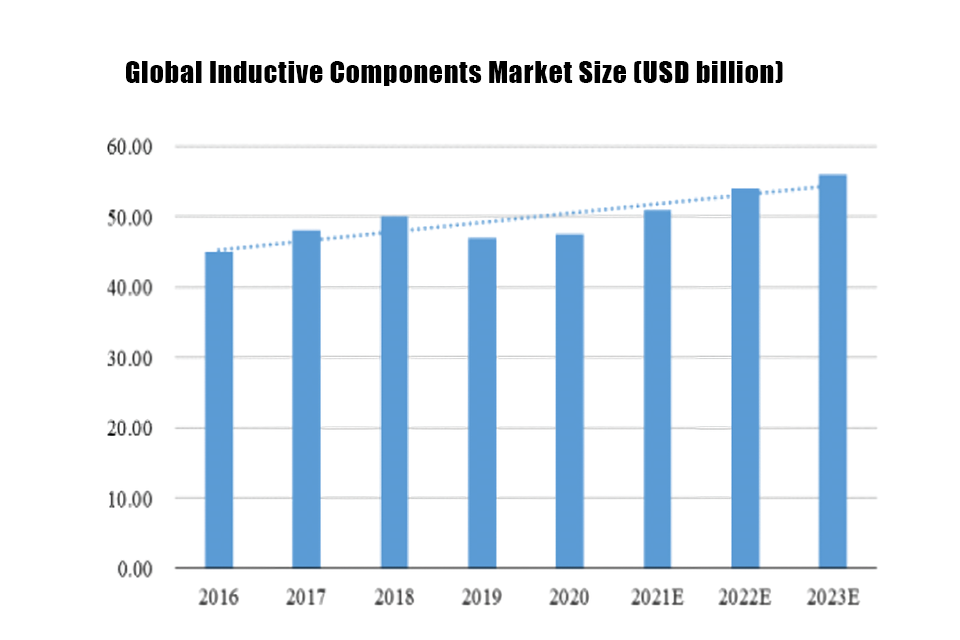

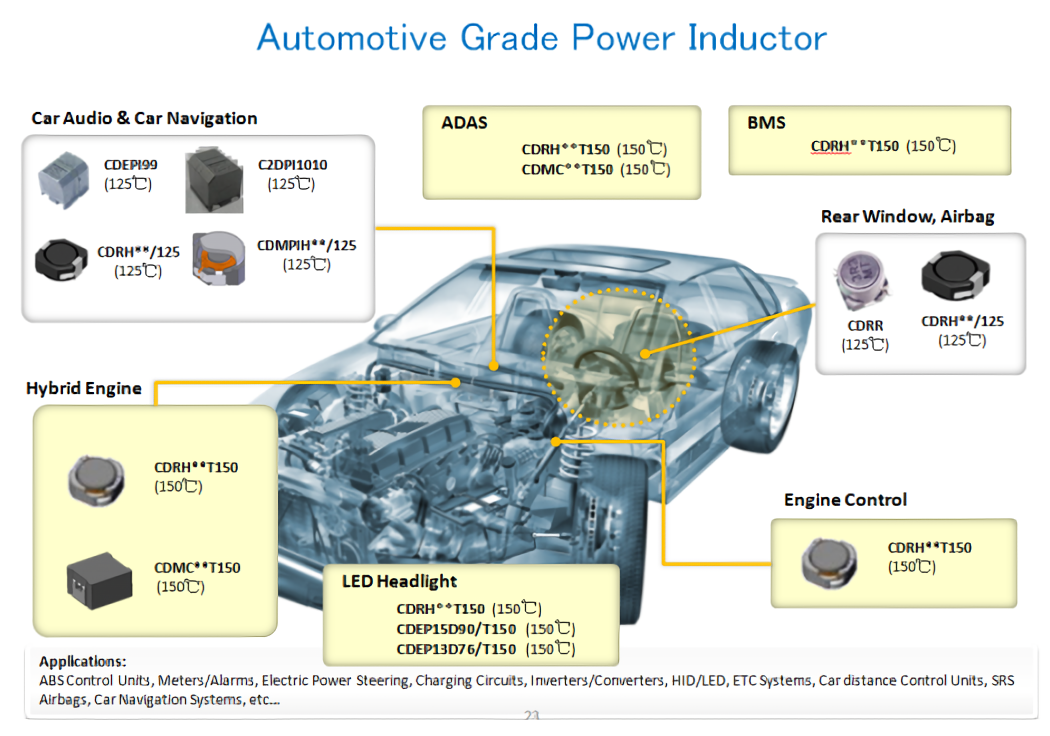

Inductors play a critical role in driving automotive technology innovation and sustainability. These components help in improving all aspects of vehicle performance and efficiency, thereby driving advancements in electric vehicles, safety systems, and energy management. Global inductive components sales reached USD 4.6 billion in 2019 and with the growing market demand, the global inductive components market space is expected to surpass USD 5 billion by 2023.

Let's seize this opportunity to create a more sustainable future for the industry, while promoting economic growth and technological innovation. To learn more about our high-efficiency inductor products, please contact our team.